Leander, TX Local Spray Foam Insulation Contractor for Homes and Businesses

Selecting a Leander, TX Local Spray Foam Insulation Contractor for Homes and Businesses requires focusing on the quality of materials, installation expertise, and how well the insulation suits your building type. Spray foam insulation stands out as a solution that improves energy efficiency, controls moisture, and strengthens building envelopes for both residential and commercial properties. The choice between open-cell and closed-cell foam depends on your specific needs such as thermal performance, soundproofing, and budget.

This article provides detailed information about spray foam types, relevant services, key factors to consider before deciding, and answers to common questions. Whether you need insulation for a new home, a pole barn, or a commercial facility, understanding your options will help you make an informed choice that benefits your property long term.

Spray Foam Insulation Types and Services

Spray foam insulation is a versatile product available in various forms and applications. Below is an overview of the types and related services typically offered by local insulation experts in Leander, TX:

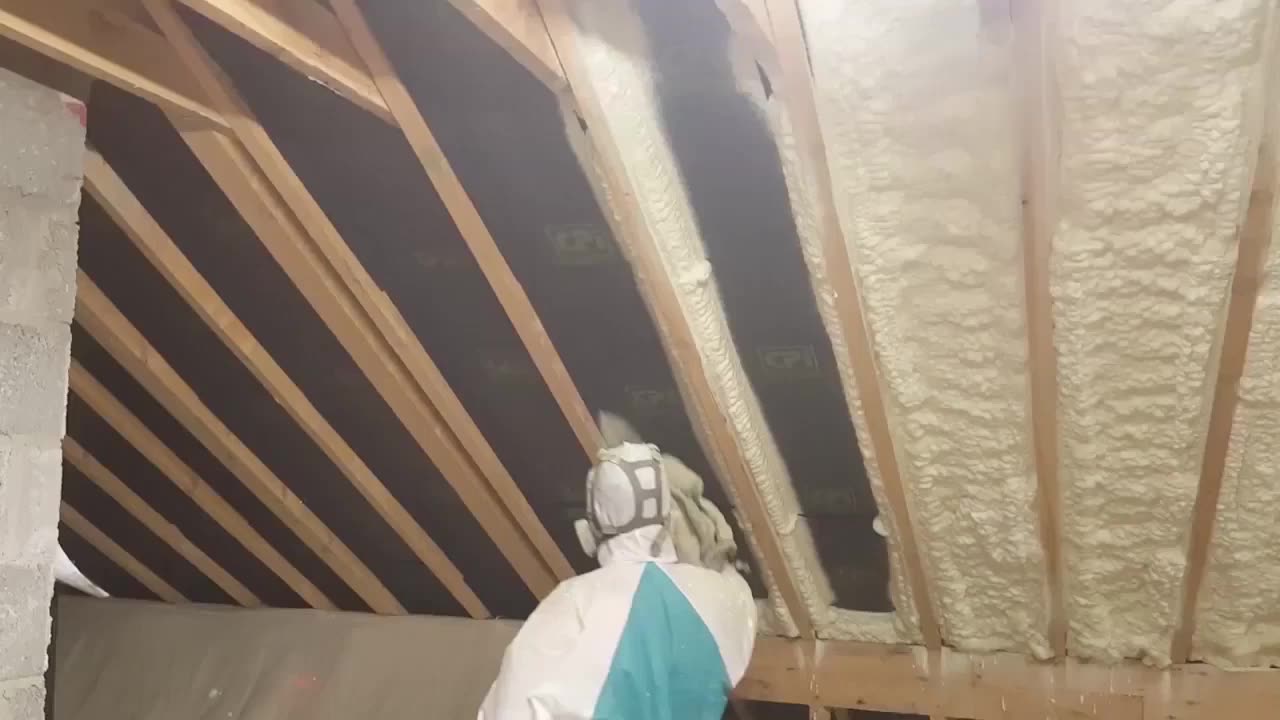

Residential Spray Foam This service focuses on insulating homes to reduce energy loss, improve comfort, and minimize noise. Residential spray foam fits walls, attics, basements, and crawl spaces.

Commercial Spray Foam Commercial applications require larger-scale solutions to enhance energy efficiency and durability in warehouses, office buildings, and retail spaces. This spray foam is formulated for greater structural support and moisture resistance.

Open-Cell Spray Foam Open-cell foam expands upon application, filling gaps and offering excellent sound dampening. Its lightweight and ideal for interior walls and ceilings where vapor permeability is acceptable.

Closed-Cell Spray Foam Closed-cell foam is denser, providing a stronger barrier against air and moisture. It has a higher R-value and adds structural strength, making it perfect for exterior walls, roofing, and pole barns.

Spray Foam Pole Barn Pole barns benefit from spray foams air sealing and insulation properties, extending building life and reducing heating and cooling costs.

Spray Foam Roofing Spray foam roofing combines insulation and a protective coating. It seals roofs, improves waterproofing, and reflects heat, lowering energy costs for commercial and residential buildings.

Mineral Wool Insulation Mineral wool offers fire resistance and soundproofing. It is often used in combination with spray foam to enhance fire safety in commercial or multifamily structures.

Insulation Removal Removing old or damaged insulation is a necessary step before applying spray foam. This ensures better adhesion and prevents future moisture or mold problems.

Interior Insulation This service involves insulating interior walls and ceilings to improve thermal comfort and soundproofing, often using open-cell foam or mineral wool.

New Construction Insulation Spray foam insulation during new construction provides a seamless air barrier and maximum energy efficiency from the start.

Roof Coatings Applied over spray foam or other roofing materials, roof coatings protect surfaces from UV rays, weather damage, and extend roof lifespan.

Polyurea Coatings These fast-curing, flexible coatings protect roofs, tanks, and concrete from corrosion and water intrusion, enhancing durability in commercial applications.

Residential Spray Foam Insulation Tailored to home environments, this service focuses on precise installation to improve energy savings and comfort year-round.

Commercial Spray Foam Insulation For larger buildings, this service ensures effective insulation with attention to vapor barriers and fire safety compliance.

Comparing Spray Foam Insulation Types and Features

|

Feature |

Open-Cell Spray Foam |

Closed-Cell Spray Foam |

Mineral Wool Insulation |

Polyurea & Roof Coatings |

|---|---|---|---|---|

|

Thermal Performance (R-value/in) |

3.53.8 |

6.07.0 |

3.03.3 |

N/A Protective coating only |

|

Sound Dampening |

Excellent |

Moderate |

Excellent |

Poor |

|

Moisture Barrier |

Low (vapor permeable) |

High (vapor barrier) |

Moderate |

Waterproof |

|

Cost |

Lower |

Higher |

Moderate |

Varies by type |

|

Application Areas |

Interior walls, attics |

Exterior walls, roofs |

Walls, ceilings |

Roofs, tanks, concrete |

|

Air Sealing |

High |

Very high |

Low |

Surface protection only |

|

Flexibility |

Expands greatly |

Rigid |

Semi-flexible |

Flexible coating |

|

Longevity |

20+ years |

30+ years |

1520 years |

1020 years |

|

Use Cases |

Residential insulation |

Commercial & residential |

Fire-resistant spaces |

Roof longevity & waterproofing |

Factors to Consider When Choosing Spray Foam Insulation

Before committing to a spray foam insulation project, take these factors into account:

Building characteristics influence the choice of insulation. New construction offers the flexibility to use closed-cell foam for maximum efficiency, while older buildings might benefit from open-cell foam due to its ability to fill irregular spaces without adding excessive weight.

Local climate impacts material performance. Leanders hot and humid summers call for insulation that can control moisture and heat transfer, which makes closed-cell spray foam an excellent option in many cases.

Soundproofing needs determine foam choice. Open-cell spray foam and mineral wool provide superior sound absorption, valuable for residential spaces or businesses seeking quieter environments.

Budget constraints often influence the decision. Open-cell spray foam is generally more affordable, but closed-cell foam delivers better long-term energy savings due to higher insulation values.

Moisture control is critical. Closed-cell foam creates a vapor barrier that prevents moisture penetration, protecting structures from mold and rot. For areas prone to moisture, this makes a significant difference.

Existing insulation conditions affect preparation. Removing old insulation ensures spray foam adheres correctly and performs optimally, avoiding problems like trapped moisture or reduced insulation effectiveness.

Service scope matters. Beyond insulation, additional services like roof coatings and polyurea applications extend the protection and lifespan of your building.

What to Expect from Professional Spray Foam Insulation Services

Local spray foam installers provide thorough evaluations before starting a project. They assess wall cavities, roof conditions, and ventilation needs to recommend the best insulation type. Experienced teams apply foam precisely to avoid gaps and ensure complete coverage.

Spray Foam Tech offers comprehensive services beyond insulation, including insulation removal, mineral wool installation, roof coatings, and polyurea protective layers. This combination ensures your building is insulated, sealed, and shielded from environmental damage.

For commercial properties, special attention goes to fire codes, vapor barriers, and structural requirements. Residential projects focus on comfort, energy savings, and sound control.

Common Questions About Spray Foam Insulation in Leander

Can I mix open-cell and closed-cell foam in the same building? Yes. Many projects use open-cell foam inside walls and closed-cell foam on exterior walls or roofing for balanced performance.

Does spray foam insulation require removal of existing insulation? If old insulation is damaged or obstructs foam application, removal is necessary. This creates a clean surface for the new insulation to adhere.

How long does spray foam last? Spray foam typically lasts 20 to 30 years or more when installed properly and protected from UV exposure.

Is spray foam safe for residential use? Professional spray foam teams use materials and methods approved for residential applications, ensuring safety and compliance with local codes.

Can spray foam insulation help reduce noise? Yes. Open-cell spray foam and mineral wool significantly reduce sound transmission between rooms and from outside sources.

Additional Frequently Asked Questions

Q1: What makes closed-cell spray foam better for roofs? Closed-cell foam offers superior moisture resistance and structural support, ideal for roofing surfaces exposed to weather.

Q2: How quickly does spray foam cure? Spray foam cures within minutes, but full curing and off-gassing take about 24 hours, during which occupants should avoid the area.

Q3: Will spray foam insulation increase home value? Quality spray foam insulation improves energy efficiency, comfort, and structural integrity, all of which can raise property value.

Q4: What certifications should a spray foam professional have? Look for installers certified by reputable industry organizations and experienced with both residential and commercial spray foam applications.

Q5: Can spray foam be applied in humid environments? Yes, but closed-cell spray foam is preferred in humid conditions due to its vapor barrier qualities that prevent moisture buildup.

Conclusion

For homes and businesses in Leander, TX, selecting the right spray foam insulation solution is crucial for energy efficiency, durability, and comfort. Understanding the differences between open-cell and closed-cell foam, along with complementary services like mineral wool insulation and roof coatings, helps create a complete, effective insulation strategy. Consider building type, climate, moisture levels, and budget before deciding. Reliable local insulation experts ensure the job is done correctly, maximizing long-term benefits.

Ready to Improve Energy Efficiency and Comfort?

If youre seeking residential spray foam insulation solutions tailored to your needs, Spray Foam Tech offers expert services across residential and commercial spray foam insulation, pole barn insulation, roof coatings, and more. Their professional team delivers precision, durability, and performance with trusted materials and industry knowledge.

Schedule your custom consultation with Spray Foam Tech today. Contact: Spray Foam Tech ? (737) 777-9590 ?? oldworldtx@hotmail.com

Reviewer: Maria Lopez reviewed the article and brought 12 years of insulation industry experience to improve the guidance. Practical tips were added, and the content was made clearer and more useful for contractors working in the field every day.