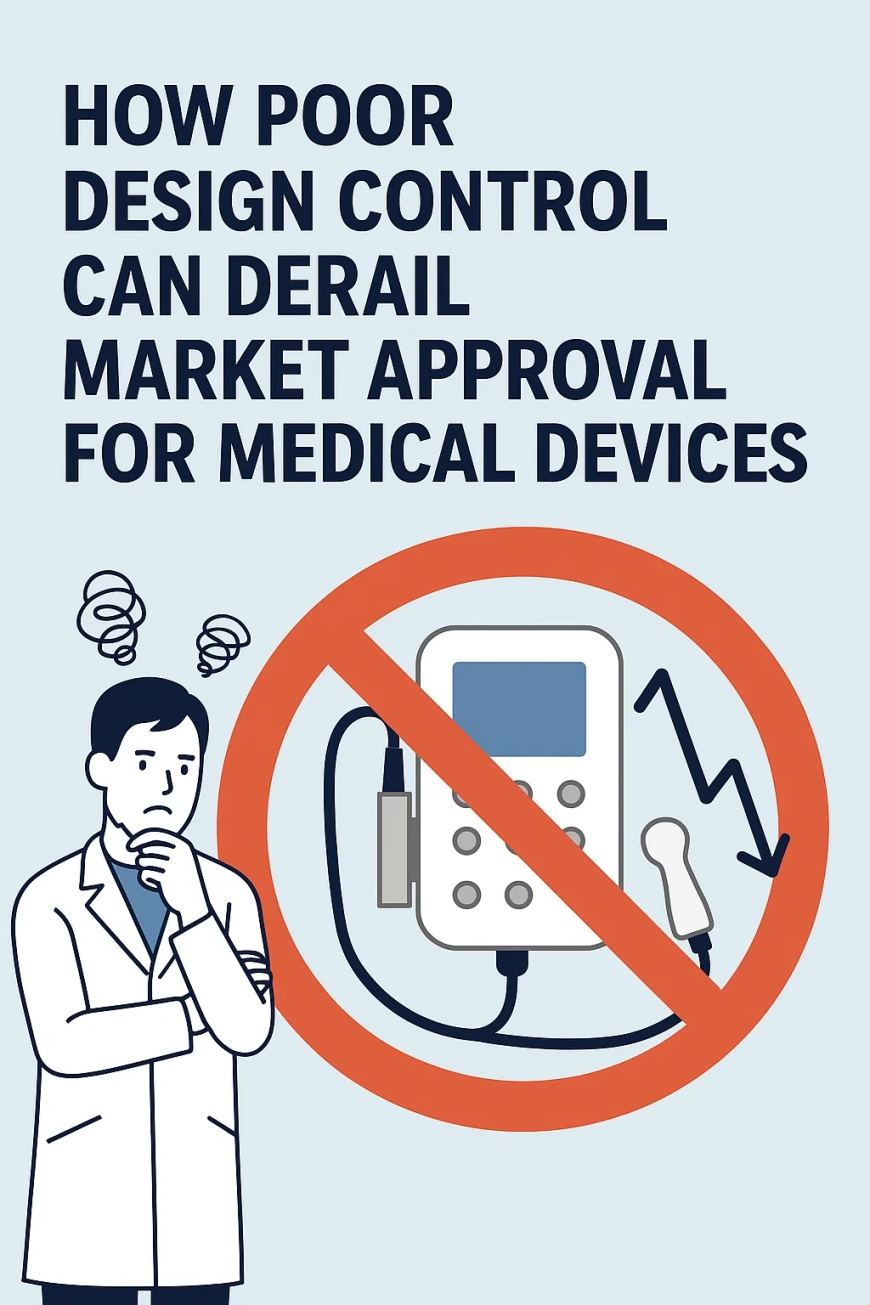

How Poor Design Control Can Derail Market Approval for Medical Devices

Explore how poor design control can hinder market approval for medical devices. Learn about the risks associated with inadequate design documentation, insufficient traceability, and non-compliance with regulatory standards, and how robust design control systems can prevent delays and ensure successful product approvals.

Understanding Regulatory Rejection: The Impact of Design Control for Medical Devices

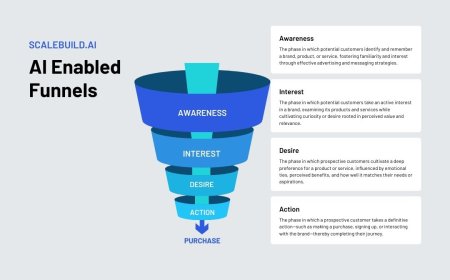

Design Control for Medical Devices is a foundational pillar of regulatory submission. Poor adherence to its framework can significantly undermine a device manufacturer's ability to gain timely market approval. From the FDA's 21 CFR 820.30 requirements to ISO 13485 clauses, regulators scrutinize the application of structured processes that govern product design and development. Inadequacies in design input, output, verification, or validation can trigger FDA warning letters or EU MDR nonconformance observations.

Medical device design controls are not just procedural mandatesthey are compliance mechanisms that ensure a device is safe, effective, and fit for its intended use. When manufacturers lack digital traceability or comprehensive risk integration within their design control medical device workflows, it directly compromises product quality and safety.

Breakdown of Compliance: Where Design Control for Medical Devices Fails

Failures in design control for medical devices often stem from disconnected processes, lack of standardized documentation, or incomplete verification records. In legacy or partially manual systems, design changes are not consistently reviewed or cross-referenced with risk files, clinical evaluations, or regulatory requirements.

Regulators expect a closed-loop system where design history files (DHF), device master records (DMR), and risk management documentation are consistently aligned. Without this, market approval for new products or Class II/III devices may be significantly delayed or denied altogether. The need to trace design changes to their original input requirements is a fundamental expectation in medical device design controls, and noncompliance in this area leads to critical audit findings.

Lack of Risk-Based Planning Undermines Design Control Medical Device Strategy

Medical device design controls must be driven by a risk-based approach. One of the most overlooked aspects of poor design control for medical devices is inadequate risk analysis during the initial concept and design input phases. When companies fail to apply ISO 14971 risk methodologies or overlook integrating risk into design outputs, they are setting themselves up for regulatory scrutiny.

For example, devices submitted for FDA 510(k) or PMA review are increasingly assessed for how well the design process addressed foreseeable hazards. Poorly maintained risk control matrices or isolated documentation systems create serious gaps in design traceability. These gaps highlight a fundamental flaw in the manufacturer's quality and safety mindset.

Inadequate Use of Quality Management Software in Design Workflows

Design control medical device workflows that are not supported by robust Quality Management Software (QMS) are at a significant disadvantage. Without a centralized platform, manufacturers often struggle with version control, incomplete audit trails, and manual errors in documenting design reviews and approvals.

An advanced Quality Management Software solution integrates design inputs, verification test protocols, and validation results with risk and regulatory data. It ensures that medical device design controls are properly documented, accessible, and audit-ready. Absence of such an integrated system typically results in missing data, noncompliant design history files, and ultimately, failed submissions.

FDA Expectations and the Consequences of Noncompliance in Design Control

The FDAs Quality System Regulation (QSR) mandates strict compliance with design control requirements. Common violations include incomplete user needs assessments, missing verification protocols, and failure to validate the design under simulated or actual use conditions. Such violations often lead to Form 483 observations, warning letters, or, in severe cases, import bans.

Design control for medical devices is often where startups and mid-sized enterprises fall short, especially when they attempt to scale without digitized infrastructure. The medical device design controls expected by the FDA are increasingly sophisticated, requiring real-time documentation, collaborative review environments, and risk-based documentation.

Impact of Poor Design Control Medical Device Documentation on EU MDR Submissions

European Union MDR regulations, especially Annex II and III, impose strict requirements on technical documentation, including design verification and validation data. Poor design control medical device practices, such as incomplete clinical evaluations or inconsistent labeling information, directly affect a manufacturers ability to CE mark their products.

Design control for medical devices must align with global submission strategies. For manufacturers targeting both FDA and EU MDR approvals, any discrepancies in design documentation between regions can lead to costly remediation efforts and delayed market entry. Without harmonized digital documentation, the likelihood of failed conformity assessments increases.

How Lack of Design Input Traceability Affects Quality and Safety

One of the core requirements in medical device design controls is the traceability of design inputs to final outputs and risk controls. Without this traceability, manufacturers cannot adequately demonstrate that the device will perform safely under expected use conditions. Poor traceability is not just a compliance issue; it is a quality and safety risk that can result in post-market surveillance issues or product recalls.

Design control for medical devices, when executed through a robust Quality Management Software platform, can ensure that every design input is documented, reviewed, approved, and mapped to corresponding outputs, verification protocols, and validation evidence. This systematic approach strengthens the overall safety profile of the product.

Role of Design Reviews in Avoiding Late-Stage Failures

Design reviews are mandated checkpoints where cross-functional teams assess whether a product is progressing according to regulatory, safety, and performance criteria. Inadequate or poorly documented design reviews are among the top contributors to late-stage product failures and submission delays.

Medical device design controls that leverage structured, time-stamped design review processes with documented outcomes can help identify risks early. With design control medical device software, teams can schedule reviews, track action items, and ensure that all critical feedback is incorporated before submission. This level of documentation supports both compliance and continuous improvement.

Integrating Human Factors and Usability Engineering into Design Control

Increasingly, the FDA and EU MDR expect manufacturers to incorporate human factors and usability engineering into the design control process. Failing to include these elements can derail a submission, particularly for devices used in home healthcare or high-risk settings.

Design control for medical devices must consider usability risks as design inputs and validate that the final product reduces user error. With integrated Quality Management Software, teams can embed usability studies, training protocols, and simulated-use testing results into the design control process, creating a defensible case during regulatory reviews.

Aligning Design Control for Medical Devices with Post-Market Feedback

To achieve a closed-loop system, feedback from post-market surveillance, complaint investigations, and CAPA (Corrective and Preventive Actions) should inform future design activities. Organizations that fail to connect post-market data with ongoing design processes are likely to repeat mistakes and suffer from recurring nonconformances.

Using Quality Management Software to align CAPA insights with design inputs, risk controls, and user requirements helps create a proactive compliance strategy. This reinforces the accountability and robustness of medical device design controls and demonstrates a culture of continuous improvement to regulators.

Conclusion: Why ComplianceQuest is Vital for Design Excellence in 2025

As regulatory demands continue to evolve and product complexity increases, the margin for error in design control for medical devices is narrowing. ComplianceQuest offers a cloud-native platform that seamlessly connects design inputs, risk management, design outputs, and regulatory submission documentation in one integrated environment.

With built-in support for medical device design controls, ComplianceQuest empowers manufacturers to meet FDA and EU MDR requirements with confidence. Its ability to link design reviews, usability data, post-market feedback, and CAPA processes into a cohesive Quality Management Software suite ensures that manufacturers not only meet compliance standards but exceed expectations. In 2025, choosing ComplianceQuest means choosing smarter, faster, and safer market access for innovative medical devices.